So it’s a rainy night, and a powerful storm is unleashing its fury outside. Relentless rainfall can trigger worry about basement or crawl space flooding. It’s an all-too-familiar scenario for many homeowners, especially those in areas prone to heavy rain.

Flooding is common in certain regions of the United States, even in areas not known for heavy rainfall or snowfall. The Federal Emergency Management Agency (FEMA) notes that over 20% of all flood insurance claims come from locations outside high-risk flood zones.

Enter the sump pump system, the unsung hero in the battle against basement flooding. It tirelessly keeps your lower living spaces safe and dry, preventing floodwater from wreaking havoc on your property. But have you ever wondered about the components that permit this system to operate smoothly?

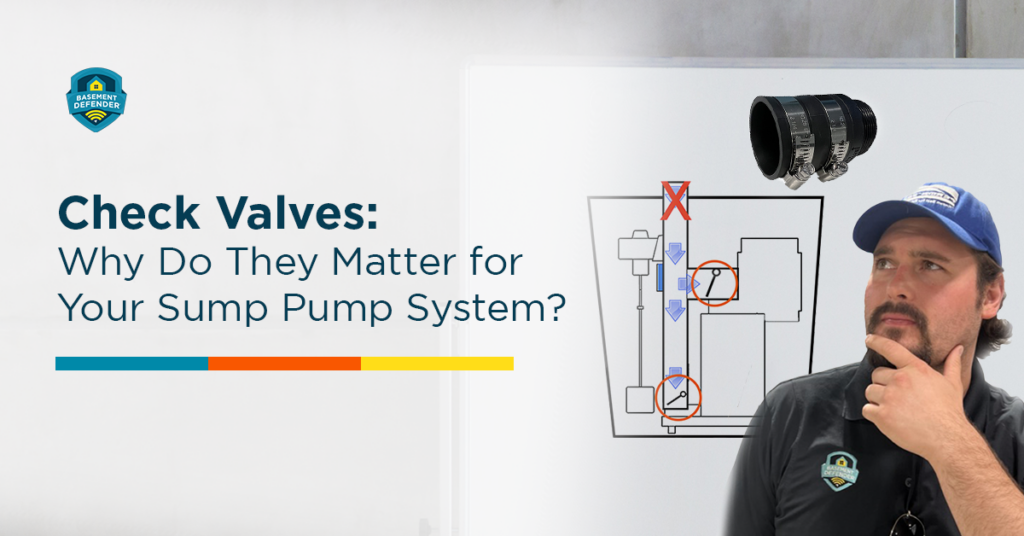

That’s where your sump pump check valve comes into play. This article highlights an often overlooked but central part of your property protection concerns.

To truly appreciate your basement check valve, you must understand what it is and how it operates.

A check valve is a simple yet indispensable device that controls the flow of liquids. It allows them to move in one direction while blocking any reverse flow. It acts like a soccer goalie for your plumbing, directing water in the right direction and preventing it from returning to the sump pit.

Check valves are ingeniously designed. They comprise a valve with an inlet and outlet containing a movable element known for its shape. This element pivots or lifts to allow water to flow in the intended direction without obstruction.

When water tries to reverse its course, the flapper quickly closes to seal off the passage. Here’s a diagram of a ball-type check valve with a reset spring to prevent backflow.

Why are they essential for sump pump systems?

A check valve’s primary function is to prevent water from re-entering your sump pit or basement, which serves two critical purposes.

Firstly, check valves reduce the workload on your pump by stopping water from flowing back into the pit. Without a check valve, the pump would have to constantly fight against gravity and the weight of the water it just expelled every time it cycles—like bucketing out a sinking ship.

This extra effort can lead to wear and tear, potentially leaving you to look for a sump pump replacement. With a check valve, the pump can operate more smoothly, extending its lifespan and ensuring it’s ready to spring into action when needed.

Secondly, check valves help maintain the water pressure in your discharge pipe. When the sump pump discharge passes the valve, it seals shut immediately to create a closed system. This seal keeps consistent pressure for a smooth, uninterrupted flow away from your basement.

Selecting the ideal check valve for your sump pump system is crucial, as it won’t function optimally without one! Here’s a guide to help you make an informed decision:

There are four main types of check valves differentiated by the moving element that stops backflow: swing, spring, ball, and flapper valves.

Swing and flapper valves are mostly used in sump pump systems due to their reliability and low maintenance requirements, which can simplify cleaning sump pump components. However, consulting your sump pump manufacturer’s recommendations is essential to meet your needs.

The check valve’s size must match your discharge pipe’s diameter for proper function. Most discharge pipes use PVC with diameters ranging from 1.25 to 3 inches. An incorrectly sized valve can lead to inefficiencies or system failures. Triple-check your check valve’s dimensions to ensure compatibility with your pump and discharge pipe.

Choose a check valve material and design compatible with the type of water your sump pump handles. A standard check valve may suffice for clear water, but consider corrosion-resistant materials like PVC or stainless steel if your sump pump deals with dirty or corrosive water.

Additionally, some designs are better suited to handling debris-laden water, which can clog or damage other valve types.

Depending on where you live, local building codes and regulations may dictate the type of check valve you should use. Check with your local authorities or building codes to ensure compliance and safety.

If you’re unsure which check valve is best for your sump pump system, don’t hesitate to consult professionals or experts—ideally, your sump pump provider. They can give you valuable insights that may not be readily apparent to a non-expert.

When it comes to basement defence, check valves emerge as unsung champions in ensuring your basement and crawl space remain dry during the harshest storms. However, if you’re ready to take your flood protection to the next level, a sump pump monitor is worth considering.

Basement Defender offers cutting-edge monitoring systems tailored to your needs. You can stay ahead of issues with real-time alerts and insights for flawless sump pump operation.

Fill in the form on our contact page to learn more and shop for the ultimate protection against basement and crawl space flooding.

Roy is a respected authority in the waterproofing industry, with over 40 years of experience under his belt. His company, Perma-Seal, has earned a reputation as Chicagoland’s premier waterproofing contractor, thanks to Roy’s unwavering commitment to quality, integrity, and customer satisfaction.

His latest innovation, the Basement Defender, is a testament to his dedication to providing homeowners with the best possible protection against basement flooding, representing a major leap forward in the industry’s efforts to prevent water damage and save homeowners from costly repairs.

Use code BDFREESHIP26 at checkout to get FREE shipping